Call: 08045478804

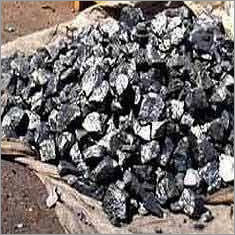

Fused Magnesite

Fused Magnesite Specification

- Usage & Applications

- Refractory, EAF lining, Slag conditioner, Manufacture of magnesia bricks, Ceramics, Metallurgy

- Melting Point

- 2800C

- Boiling point

- 3600C

- Grade

- Industrial Grade

- Purity(%)

- 96% min MgO

- Product Type

- Fused Magnesite

- Material

- Magnesite (MgCO3), Fused

- Shape

- Block/Lump/Granular

- Chemical Composition

- MgO: 96% min, SiO2: 1.0% max, CaO: 1.5% max, Fe2O3: 0.6% max

- Density

- 3.4 Gram per cubic centimeter(g/cm3)

- Size

- Customizable (Lumps/Granules/Powder)

- Weight

- As per order

- Dimension (L*W*H)

- Custom as per requirement

- Color

- Grayish White

Fused Magnesite Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 15 Kilograms Ton Per Month

- Delivery Time

- 1 Week

About Fused Magnesite

Experience the spectacular performance of our Fused Magnesite, highly popular among industrial buyers seeking premium refractory materials. Manufactured for maximum durability, this product boasts an impressive LOI of 0.2% max, high thermal conductivity, and apparent porosity below 2%. With a glorious MgO purity of 96% minimum and customizable size and packaging, it suits a wide array of applications including EAF lining, ceramics, metallurgy, and more. Enjoy stable storage and sensational export qualityavailable for immediate order. Add to cart now for unbeatable reliability and performance.

Applications & Versatility of Fused Magnesite

Fused Magnesite delivers stellar results across a wide range of media, such as industrial furnaces and kilns. Its primary applications are in refractories, EAF lining, and as a slag conditioner. Additional uses include the manufacturing of magnesia bricks, ceramics, and in various metallurgical processes. Designed for industrial use, its high purity and thermal stability make it a top choice for those requiring consistent, superior results in demanding environments.

Sample Policy, Order Processing & Export Logistics

We offer a convenient sampling policy before dispatching bulk orders, allowing clients to assess quality. Our flexible payment terms suit global buyers, and we expertly coordinate order processing for export market needs. Fused Magnesite is shipped from our designated FOB port in durable HDPE or jumbo bags. Rest assured, our team prioritizes careful packaging and prompt handling to ensure a smooth and reliable supply chain, from order placement to final delivery.

Applications & Versatility of Fused Magnesite

Fused Magnesite delivers stellar results across a wide range of media, such as industrial furnaces and kilns. Its primary applications are in refractories, EAF lining, and as a slag conditioner. Additional uses include the manufacturing of magnesia bricks, ceramics, and in various metallurgical processes. Designed for industrial use, its high purity and thermal stability make it a top choice for those requiring consistent, superior results in demanding environments.

Sample Policy, Order Processing & Export Logistics

We offer a convenient sampling policy before dispatching bulk orders, allowing clients to assess quality. Our flexible payment terms suit global buyers, and we expertly coordinate order processing for export market needs. Fused Magnesite is shipped from our designated FOB port in durable HDPE or jumbo bags. Rest assured, our team prioritizes careful packaging and prompt handling to ensure a smooth and reliable supply chain, from order placement to final delivery.

FAQs of Fused Magnesite:

Q: How is Fused Magnesite typically used in industrial applications?

A: Fused Magnesite is predominantly used in refractory materials, electric arc furnace (EAF) lining, manufacture of magnesia bricks, ceramics, and as a slag conditioner in metallurgical processes due to its high purity and excellent thermal conductivity.Q: What are the benefits of choosing your Fused Magnesite?

A: Our Fused Magnesite offers a high MgO content (96% min), low loss on ignition, and exceptional thermal stability. Its low porosity ensures long-lasting usage, making it a reliable and efficient choice for complex industrial needs.Q: Where do you export Fused Magnesite from, and what packaging options are available?

A: We export Fused Magnesite from a designated FOB port, offering secure packaging in HDPE or jumbo bags as per client requirements for global shipment.Q: What is the typical process and timeline for sample dispatching and order fulfillment?

A: Sample requests are processed promptly to ensure our clients can evaluate quality before placing larger orders. Upon order confirmation, production and dispatch are managed efficiently to meet agreed delivery schedules.Q: How can buyers customize the size and quantity of Fused Magnesite for their specific needs?

A: Clients can specify their desired dimensions, weight, and shape (block, lump, granular, or powder) when placing an order, ensuring the product meets exact technical requirements for individual applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Ores & Minerals Category

Moly Oxide

Price Range 100.00 - 1000.00 INR

Minimum Order Quantity : 50 Kilograms

Density : 4.7 Gram per cubic centimeter(g/cm3)

Size : Customizable

Metal Type : Transition Metal Oxide

Weight : 25 kg Bag

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry