Calcium Silicide Cored Wire

Calcium Silicide Cored Wire Specification

- Feature

- High Reactivity, Uniform Composition, Low Impurity

- Product Type

- Calcium Silicide Cored Wire

- Material

- Steel Strip with Calcium Silicide Powder Core

- Shape

- Round Coiled Wire

- Purity

- 99%

- Dimension (L*W*H)

- 13 mm diameter (typical), length as per coil specification

- Grade

- Industrial

- Application

- Steelmaking, Deoxidizer, Desulfurizer, Inoculant in Foundry

- Color

- Gray

- Storage Conditions

- Dry, Covered, Away from Moisture

- Core Composition

- Calcium Silicide Powder

- Standard

- ASTM/BIS/JIS compliant

- Wire Thickness

- 9 mm to 13 mm

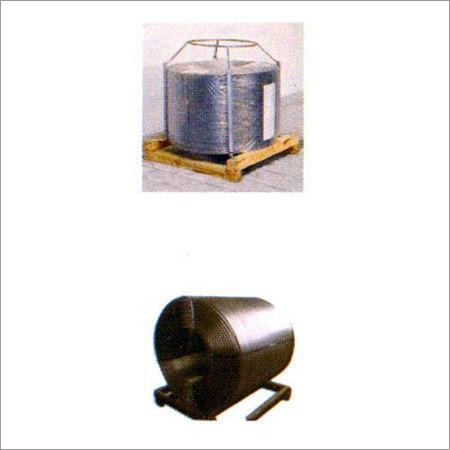

- Packing Type

- Steel Drum or Coil Wrapped

- Shelf Life

- 24 months

- Melting Point

- ~1000°C

- Usage

- Direct Addition to Molten Metal

- HS Code

- 7202.99

Calcium Silicide Cored Wire Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 5 Kilograms Ton Per Month

- Delivery Time

- 1 Week

About Calcium Silicide Cored Wire

We are reckoned as one of the reliable manufacturers, suppliers and exporters of Calcium Silicide Cored Wire. These wires are manufactured using excellent quality material by utilizing modern technology to meet the international quality standards. Premium quality material is used in the packaging of these cored wires to ensure their safe transit. Calcium Silicide Cored Wire is high in demand due to its high strength, longer service life and durability.

Specifications :

|

Product |

Specifications |

Packing |

Origin |

|

Calcium Silicide Cored Wire |

Si: 58% min Ca: 30% min S: 0.5% max P: 0.02% max C: 2% max Wire Diameter: 13 mm +/-0.5mm Powder Weight: 230+/- 5gm / meter Steel Weight: 160+/- 5gm / meter Wire Thickness: 0.4 mm +/-0.3 mm Length of coil: App. 5200 m Coil Height: 1200mm Coil ID: 550 mm Coil OD: 1100 mm |

In Pallets Al: 1.5% max |

Chin |

Optimized Metallurgical Performance

Our Calcium Silicide Cored Wire is engineered for precise and uniform metallurgical treatment. Its high reactivity and purity make it ideal for steelmakers seeking better control over deoxidation and desulfurization processes. The specialized wire structure allows consistent delivery of calcium silicide into molten steel, improving product quality through enhanced chemical reactions and minimized impurities.

Customizable Wire Solution

Available in round, coiled forms with a typical diameter of 13 mm, and customizable length options, this wire adapts well to various foundry and steelmaking requirements. The robust steel strip ensures durability, while the high-purity core ensures effective metallurgical intervention. Bulk shipments come in secure steel drums or coil wrapping, suiting different scale operations and handling preferences.

FAQs of Calcium Silicide Cored Wire:

Q: How is Calcium Silicide Cored Wire used in steelmaking and foundry applications?

A: The wire is introduced directly into molten steel or metal, where it rapidly melts (melting point ~1000C) and releases calcium silicide. This promotes efficient deoxidation, desulfurization, and acts as an inoculant, enhancing alloy quality and consistency.Q: What are the benefits of using a Calcium Silicide Cored Wire with a uniform composition and high reactivity?

A: Uniform composition ensures consistent treatment results, while high reactivity means it reacts quickly and efficiently with molten metals, improving metallurgical properties and reducing unwanted impurities in steel and cast iron.Q: Where should Calcium Silicide Cored Wire be stored to maintain its shelf life and quality?

A: Store the wire in a dry, covered area away from moisture to prevent degradation. Following these storage guidelines helps maintain its 24-month shelf life and reliable performance.Q: What safety and process guidelines should be followed when handling Calcium Silicide Cored Wire?

A: Operators should use the wire as directedby direct addition to molten metaland maintain proper storage. Handling precautions should be in place due to its reactive nature and high temperature in steelmaking environments.Q: Which standards does this Calcium Silicide Cored Wire comply with?

A: The wire adheres to global standards such as ASTM, BIS, and JIS, ensuring product reliability, quality, and compatibility for steelmakers and foundries in India and worldwide.Q: What are the main applications of Calcium Silicide Cored Wire in industrial settings?

A: Main uses include deoxidizing and desulfurizing agents in steelmaking, as well as an inoculant in foundries to enhance mechanical properties and minimize detrimental elements in finished metal products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry